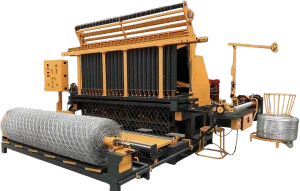

Grass Fences and Their Advantages

Reduced Errors and Waste

High Accuracy: With automated processes, these machines can eliminate human errors such as miscalculations, missed steps, or improper usage, which often lead to product defects or waste.

Minimized Waste: Automated machines use smart systems to adapt to changing variables or demands, enabling them to operate with minimal waste.

Safety and Security

Built-in Safety Features: Many fully automated machines are equipped with safety sensors, emergency shutoff features, and protective covers to minimize the risk of accidents and ensure operator welfare.

Remote Monitoring: Some machines offer remote monitoring capabilities, allowing managers to oversee operations and troubleshoot from a distance.

Customization and Flexibility

Programmed for Variety: Fully automated machines can be reprogrammed or adjusted to accommodate different tasks or product varieties, providing flexibility in production. Can Adapt to Changing Demands: Depending on the model, these machines can adapt to changes in production needs and offer scalable solutions that grow with the business.

Integration with Other Systems

Automation Systems: Fully automated machines can be integrated with other automated systems such as conveyors, packaging machines, or storage systems to create a fully automated production line.

Data Integration: Many modern machines have the ability to connect with ERP systems and cloud-based platforms, enabling easy data collection, analysis, and decision-making.

Quality Control

Integrated Quality Controls: Some fully automated machines come with built-in quality control systems that can detect product defects during the production process. This minimizes the need for post-production inspections.

Traceability: Automated systems typically track and record data for each product, allowing businesses to perform backward traceability throughout the production process for quality assurance and compliance purposes.

Lower Maintenance Costs

Self-Diagnosis and Alerts: Many fully automated machines feature built-in diagnostic tools that alert operators when maintenance is needed or when something is out of place. This reduces downtime and helps prevent major breakdowns.

Longer Lifespan: Due to their precise and consistent operations, these machines generally require less repair over time and have a longer service life.

Compact Design

Space-Saving: Many fully automated machines are designed to be compact and take up less space, which is particularly beneficial for businesses operating in smaller facilities.

Modular Installation: Some machines offer modular components that allow businesses to upgrade or expand their capabilities without having to replace the entire system.