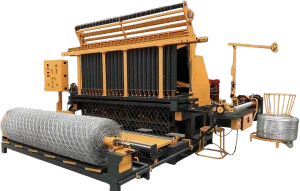

Our fully automated machines are designed to streamline operations, increase productivity, and reduce human labor across various industries. Here are some of the top features of LIFTAWORLD MAKİNA’s fully automated machines:

1. Efficiency and Productivity

High-Speed Operation: Fully automated machines operate at faster speeds compared to manual or semi-automatic alternatives, significantly boosting productivity.

Continuous Operation: These machines can run for extended periods without human intervention, ensuring 24/7 operation and minimizing downtime.

2. Precision and Consistency

Accurate Performance: Automated machines deliver consistent results with minimal errors. They are designed to perform tasks with precise measurements, ensuring uniformity and quality.

Reduced Variability: Operating under predefined conditions, fully automated machines minimize human error and the variability in output, providing consistent quality.

3. Reduced Labor Requirements

Minimal Human Intervention: Once programmed, fully automated machines require little to no human involvement in their operation, freeing up labor for more complex tasks.

Cost Efficiency: By reducing the need for manual labor, businesses can lower operational costs over time and reallocate employees to higher-value tasks.

4. Energy Efficiency

Optimized Resource Usage: Fully automated machines are designed to use energy, materials, and resources more efficiently, reduce waste, and lower operating costs.

Adaptive Energy Use: Some automated machines can further optimize energy consumption by adjusting it according to the task at hand.

5. Advanced Control and Monitoring

Programmable Systems: Fully automated machines are typically controlled by sophisticated software or programmable logic controllers (PLCs), providing precise task control and real-time monitoring.

Real-Time Diagnostics: Many machines come equipped with sensors and automated diagnostics that detect issues instantly, ensuring smoother operations and reducing the likelihood of machine breakdowns.